With its long and interesting history, the modern-day zippers come in a plethora of styles, constructed with the use of many different parts for every unique style. The zipper parts themselves are divided into other types based on several factors like the material used, functions, features, and manufacturing process.

With the vastness of available varieties, confusion usually arises when the need to purchase one appears like when a zipper malfunction occurs. This is why it is very hard to determine which zipper fits your specific needs.

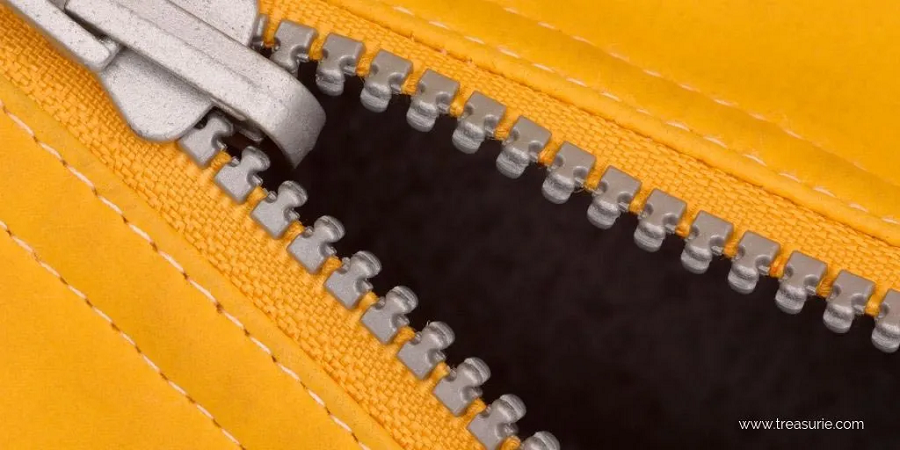

The metal zippers are some of the most common and popular types that are used on many goods and items. But, have you ever wondered how these metal zippers are made?

The manufacturing process of metal zippers is fundamentally divided into four stages and these are dyeing, chain production, slider manufacturing, and the finished product. The dyeing of metal zippers dyeing is carried out before the production of the teeth chain.

When it comes to the teeth shape of the metal zippers, there are also several options like normal round teeth corn teeth, European teeth, Y-cut teeth, and many others. Generally speaking, however, normal teeth and Y-cut teeth are the most common types you can find in the market because of their stable quality and bigger production capacity.

As far as metal zippers are concerned, the distinction is not only the shape but also the processing technology. For instance, metal zippers with normal round teeth are made of metal strips through die-stamping, with only around 60% material utilization rate. Aside from that, this manufacturing process inevitably brings the even burrs and processing marks on the teeth’s surface, having a negative effect on the sale and appearance of the zipper product.

Y-cut teeth are different as these adopt the processing technique of preformed wire. This preformed wire is sheared into small chips and these chips are then forged to create a protrusion and a concave. Finally, two legs of chips are then bent for cramping the zipper tape. The result is that the utilization rate of materials goes over 98%, with the production efficiency becoming higher and the zipper chain’s appearance quality is greatly improved. This not only simplifies the post-processing production because it also improves the zipper chain’s strength.

Main Metal Zipper Production Process

In general, the production process of metal zippers involves the following:

- Weaving tape

- Making teeth

- Assembling teeth and tape

- Flattening

- Polishing

- Dyeing

- Ironing

- Waxing

- Determining length

- Assembling accessories

- Inspection

- Packaging and storage

The following are the main materials used for the different parts of metal zippers:

- Bottom and top stopper: copper alloy, aluminum alloy

- Box and pin: zinc alloy

- Slider: zinc alloy

- Tape: cotton yarn or polyester filament

- Teeth: aluminum alloy, brass, or copper

Now that you know about the manufacturing process of metal zippers, you will find it easier to shop for the zippers you need at https://www.zippershipper.com/brass-metal-zippers.